- Saturday, 7th March, 2026

Can You Recycle a Hard Drive? Google Is Trying to Find Out

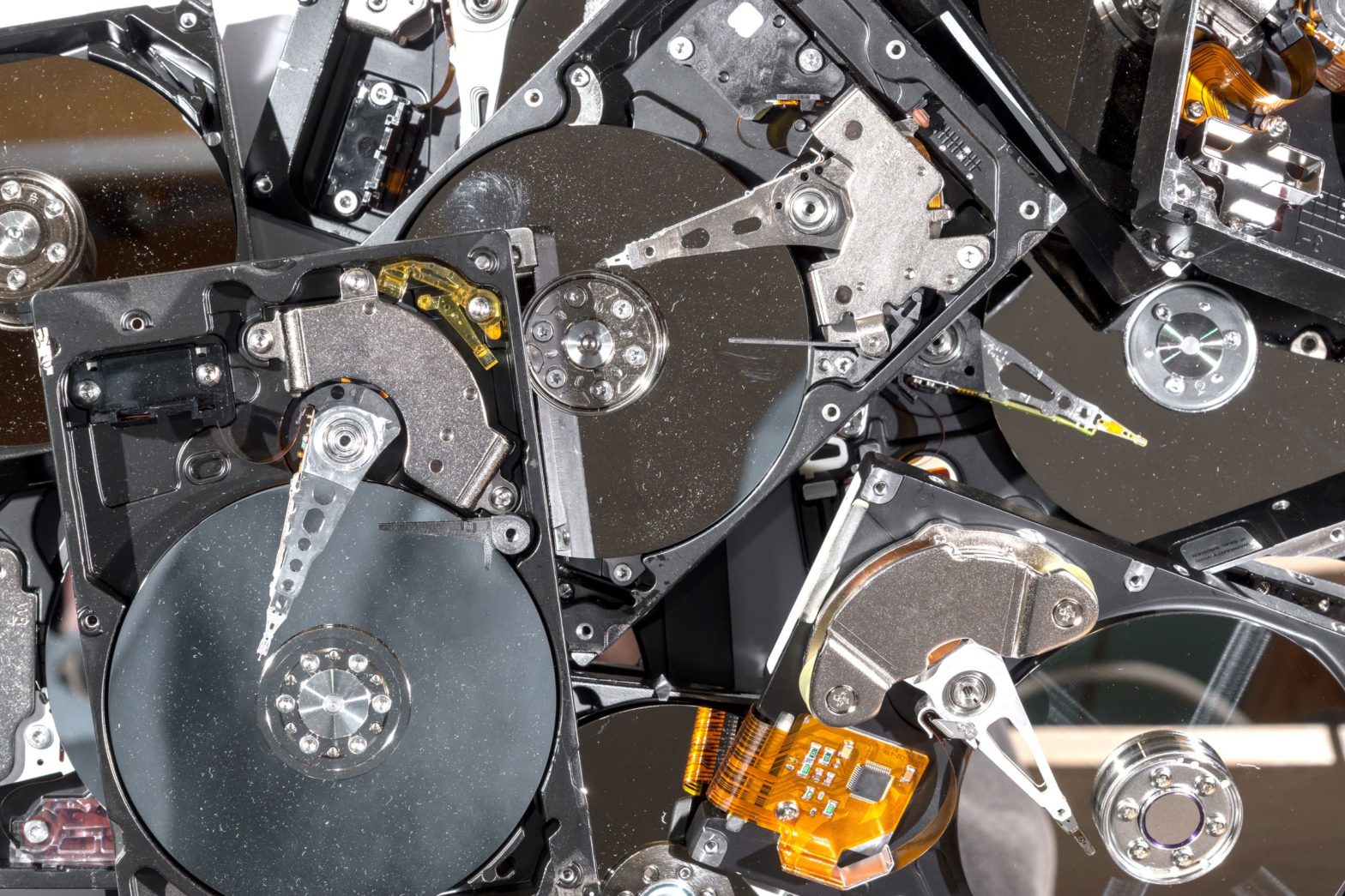

As of 2019, stakeholders produced a paper outlining several potential options, including cleaning and reusing complete hard drives, dismantling and recycling magnet parts and components, grinding old hard drive magnets and using the powder to create new ones, and extracting pure rare earth elements from shredded discs. It is labor intensive to remove magnet assemblies by hand and rare earth mining methods can be chemically or energy intensive, resulting in large quantities of waste. When it comes to placing used or recycled rare earth magnets within new discs, even the smallest supply chain tweaks are “challenging “when you have to start again from scratch with new technology.” The first moves have been taken by a few companies, though. As part of a short demonstration effort in 2018, Google, Seagate, and electronics renovator Recon text removed magnetic arrays from six hard drives and replaced them with new Seagate drives. “This was the catalyst,” says Frost, for the larger 2019 study, in which 6,100 magnet assemblies were taken from Seagate hard drives in a Google data center before being installed in fresh drives. In his opinion, this is the largest display of its kind ever, according to Frost.

In addition to showing that rare earth magnets might be harvested and recycled on a bigger scale, the results of the study will appear in the journal Resources, conservation and recycling. According to the study, repurposed magnet assemblies had an overall carbon footprint that was 86 percent lower than that of new ones. Frost claims the electricity system of the local power grid, where the data center was running, was taken into account in the cautious estimation. Reused magnets had an even lesser carbon footprint when compared to Google’s nearly 24-hour renewable energy use at this particular data center. It was unclear whether Google had any follow-up initiatives in the works, but Grist was pointed in the direction of Google’s publicly stated goal of developing an evolutionary process for regenerating rare earth magnets. According to co-author Ines Sousa, leader of Google’s supplier environmental impact program, there are still difficulties to solve before this becomes a reality.

As an example, current hard drives are extremely sensitive to microscopic particles, thus recycling magnets must be done with utmost care. a few years ago. If the design of magnets can be made constant between generations, Sousa says, “The process of reuse can evolve.” Rare earth recycling is “complicated,” according to Seagate spokesperson, and the company is “committed to working to solve it in close collaboration with customers.” His other client, computer maker Dell, is exploring a different approach to recycling, which he hopes to implement soon. On January 1, 2019, Dell, Seagate, and Recon text launched a pilot operation to rescue magnets from computer hard drives, pulverize them, mine rare earths, and use them to produce new magnets. Through this collaboration, nearly 19,000 pounds of rare earth magnets have been collected and recycled. Dell spokesman Mel Derome told Grist that the project “remains a pilot program as we continue to look for ways to evolve within our own operations.”

Despite the fact that it may be years before rare earth magnets are recycled in large quantities, the Biden administration may be able to assist speed things up. The federal government has previously funded many initiatives aimed at developing cleaner and more efficient procedures for recycling rare earth elements from magnets through the Critical Materials Institute at Ames National Laboratory. As stated in a recent government-funded assessment on enhancing supply chain resilience, there is “short-term opportunity” to extract rare earth magnets from the US government’s 4,000 data centers.